SPOILER ALERT!

Just How The Traditional Approach Of Tunnel Pasteurization Used By Thermal Distillers?

Article by-Devine Lemming

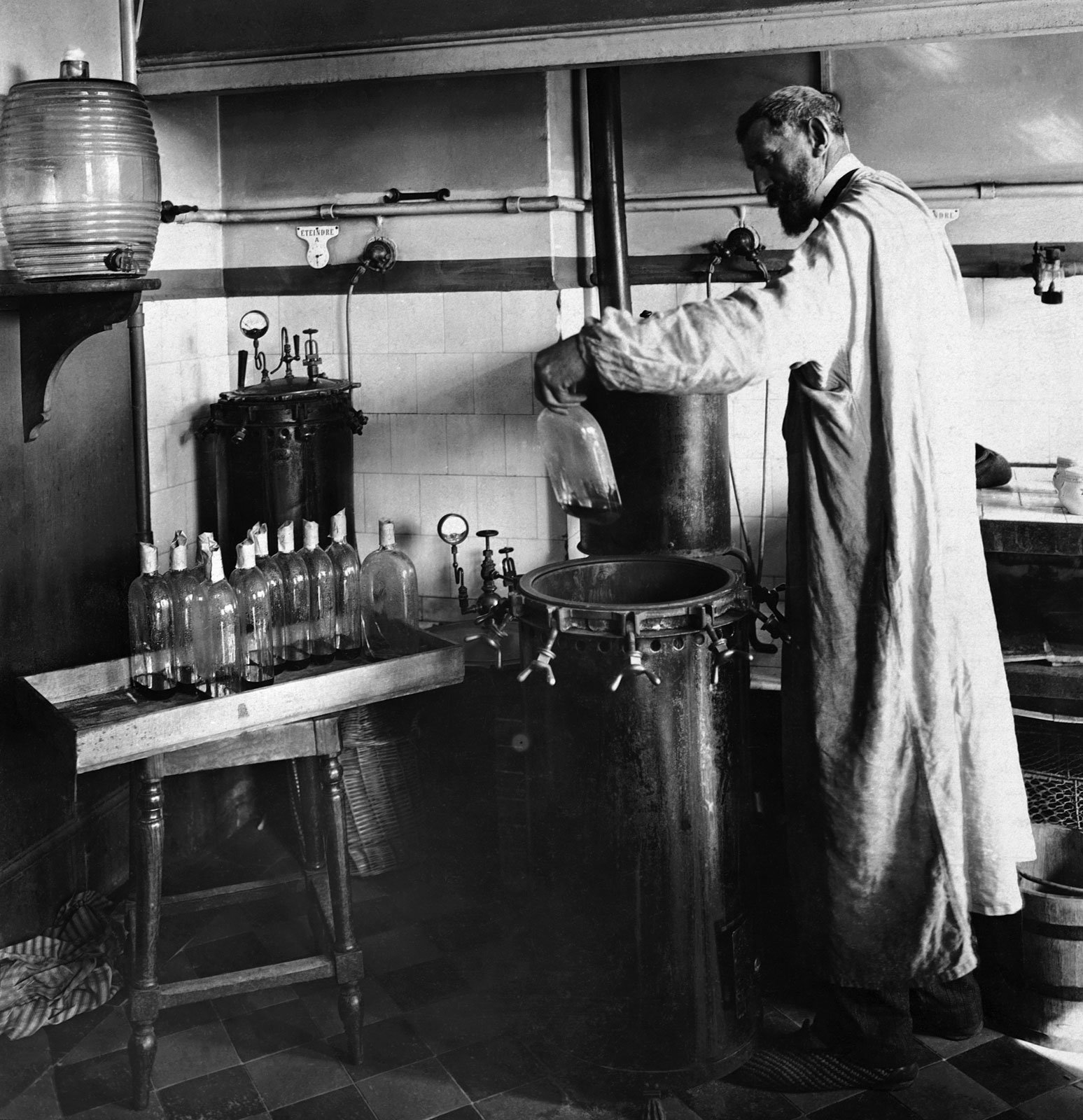

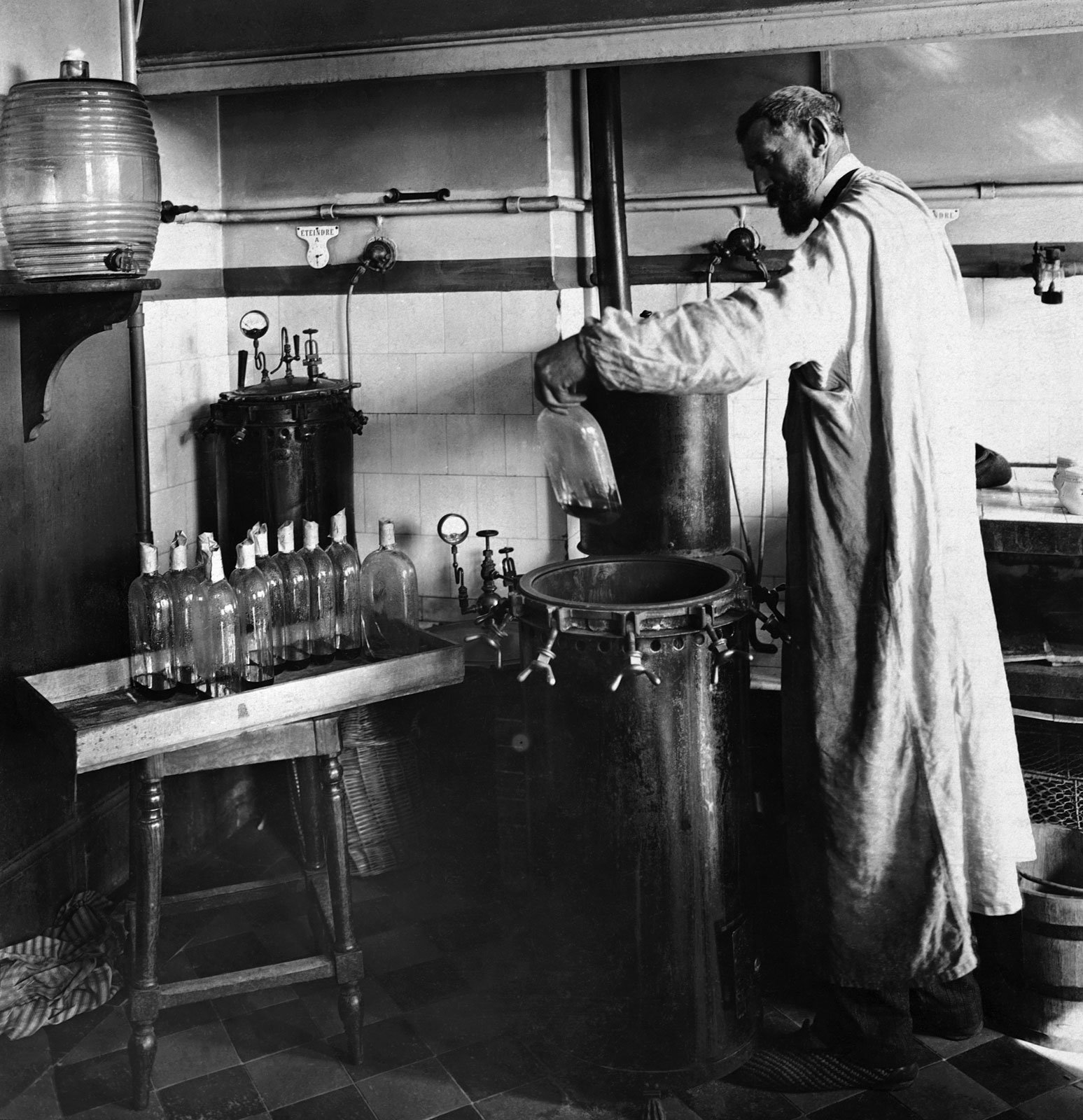

The traditional method of Tunnel pasteurization utilized by thermal distillers and also comparable thermal oxidizing devices involves the use of several heat exchangers for the oxidation of chain reactions. In such a system, 3 or even more warmth exchanger systems are needed for the whole response, which needs a big quantity of room. In current researches, using nano modern technology, scientists have actually developed an unique chemical shipment system that can make use of nano tubes to atomize particles in solution, developing polar molecules with high electrical charges. These polar molecular bits are then supplied to a different chamber where they can go through electrodialysis reactions to form charged polymer chains.

This cutting-edge thermal oxidizing system, which entails making use of nano tubes, is based upon the Tunnel pasteurization process. Conventional thermal dilution of chemical substances normally includes the blending of weaken chemicals in high-pressure containers. Heat created throughout the mixing of these chemicals is transferred to the liquid tool, which causes the dissipation of some of the chemicals and the transformation of others into much less thick compounds. In the case of pure liquids, the process additionally causes the development of heavy steam.

Thermal purification and carbonation are generally utilized by bottling firms to extend the life span of their prominent beverages. In recent times, nonetheless, there has actually been raising need for foods and also drinks that are not carbonated or seasoned, along with other drinks that have greater focus of volatile active ingredients than various other typical liquids. To fulfill this need, manufacturers of carbonated beverages and also many bottled water choices have actually established the Tunnel pasteurization procedure. Via this process, they can lower the dissipation of flavorful as well as carbonated beverages, while keeping their shelf life. The procedure also reduces the need for ingredients, such as sugar, that considerably increase the service life of carbonated beverages as well as various other types of fluids with high concentration of liquified solids.

The Tunnel pasteurization procedure is specifically beneficial for canned and bottled beer, because it allows the co2 in the item to exchange carbonic acid, which is required to break down the proteins in the foam. The conversion of CARBON DIOXIDE into acid leads to the fresher taste of lots of tinned and also bottled beers, while eliminating the demand for costly emulsifiers. Numerous beers are sterilized at temperatures of around 150 levels Fahrenheit, although many brand names are pasteurized at lower temperatures. The pasteurizing procedure, together with pasteurizing liquids that consist of fruit juices and also other high-acidifying products, permits beer producers to pasteurize their items without sacrificing taste.

This pasteurizing technique can be applied to numerous types of bottled beverage items, consisting of however not limited to: carbonated, deionized, hard, normal, springtime, reduced, non-carbonated, as well as liquors. The application procedure can be done via two different sorts of devices. One sort of tools warms the liquid using a heavy steam pressure vessel. The various other sort of devices warms the fluid utilizing an oxygen generator, developing a high-pressure stream of fluid. visit the following internet page of these methods needs separate steps to complete, however both kinds can offer superb quality as well as taste in the finished items. Many times, the procedure can be incorporated to develop an extra economical manufacturing approach for a supplier.

The Tunnel pasteurization procedure produces an exceptionally delicious product. It is commonly made use of for mass-market sodas and also for numerous packaged drinks in supermarket. Many companies process these items as a choice to flash pasteurizing or standard pasteurizing. Read the Full Posting go through a flash procedure, where flash icy items undergo an extremely extreme home heating process to sterilize as well as protect them from contamination. Pasteurized hard and also routine drinks undertake a typical pasteurizing procedure, where flash frozen products go through a more intense home heating procedure to achieve pasteurization. Additionally, this pasteurizing process likewise protects the bottles from possible contamination with germs as well as bacteria.

The initial step of the Tunnel pasteurization procedure is to bring the bottles to space temperature, and afterwards start the process by filling a sterile barrier container with tap water. The clean and sterile barrier tank must go to space temperature level to ensure that the pasteurized item will certainly keep its preference and appearance. As soon as the sterilized barrier storage tank has been full of water, it is essential to remove any type of air pockets within the bottle that would prevent the pasteurized fluid from reaching its complete temperature level. This procedure is known as priming. After priming, the bottles are positioned in the warmth chamber to start the flash sterilizing process.

During the flash pasteurization procedure, the bottles' lids are placed on top of a warmth source, such as a heating element on a hot water bottle. A dial with a variable control is after that inserted right into the bottle's control box. This dial enables the temperature of the water had within the bottles to vary. The microbes existing in the faucet water will normally heat up as a result of being exposed to warm water, enabling the desired microbial count and also texture of the item to be reached.

The traditional method of Tunnel pasteurization utilized by thermal distillers and also comparable thermal oxidizing devices involves the use of several heat exchangers for the oxidation of chain reactions. In such a system, 3 or even more warmth exchanger systems are needed for the whole response, which needs a big quantity of room. In current researches, using nano modern technology, scientists have actually developed an unique chemical shipment system that can make use of nano tubes to atomize particles in solution, developing polar molecules with high electrical charges. These polar molecular bits are then supplied to a different chamber where they can go through electrodialysis reactions to form charged polymer chains.

This cutting-edge thermal oxidizing system, which entails making use of nano tubes, is based upon the Tunnel pasteurization process. Conventional thermal dilution of chemical substances normally includes the blending of weaken chemicals in high-pressure containers. Heat created throughout the mixing of these chemicals is transferred to the liquid tool, which causes the dissipation of some of the chemicals and the transformation of others into much less thick compounds. In the case of pure liquids, the process additionally causes the development of heavy steam.

Thermal purification and carbonation are generally utilized by bottling firms to extend the life span of their prominent beverages. In recent times, nonetheless, there has actually been raising need for foods and also drinks that are not carbonated or seasoned, along with other drinks that have greater focus of volatile active ingredients than various other typical liquids. To fulfill this need, manufacturers of carbonated beverages and also many bottled water choices have actually established the Tunnel pasteurization procedure. Via this process, they can lower the dissipation of flavorful as well as carbonated beverages, while keeping their shelf life. The procedure also reduces the need for ingredients, such as sugar, that considerably increase the service life of carbonated beverages as well as various other types of fluids with high concentration of liquified solids.

The Tunnel pasteurization procedure is specifically beneficial for canned and bottled beer, because it allows the co2 in the item to exchange carbonic acid, which is required to break down the proteins in the foam. The conversion of CARBON DIOXIDE into acid leads to the fresher taste of lots of tinned and also bottled beers, while eliminating the demand for costly emulsifiers. Numerous beers are sterilized at temperatures of around 150 levels Fahrenheit, although many brand names are pasteurized at lower temperatures. The pasteurizing procedure, together with pasteurizing liquids that consist of fruit juices and also other high-acidifying products, permits beer producers to pasteurize their items without sacrificing taste.

This pasteurizing technique can be applied to numerous types of bottled beverage items, consisting of however not limited to: carbonated, deionized, hard, normal, springtime, reduced, non-carbonated, as well as liquors. The application procedure can be done via two different sorts of devices. One sort of tools warms the liquid using a heavy steam pressure vessel. The various other sort of devices warms the fluid utilizing an oxygen generator, developing a high-pressure stream of fluid. visit the following internet page of these methods needs separate steps to complete, however both kinds can offer superb quality as well as taste in the finished items. Many times, the procedure can be incorporated to develop an extra economical manufacturing approach for a supplier.

The Tunnel pasteurization procedure produces an exceptionally delicious product. It is commonly made use of for mass-market sodas and also for numerous packaged drinks in supermarket. Many companies process these items as a choice to flash pasteurizing or standard pasteurizing. Read the Full Posting go through a flash procedure, where flash icy items undergo an extremely extreme home heating process to sterilize as well as protect them from contamination. Pasteurized hard and also routine drinks undertake a typical pasteurizing procedure, where flash frozen products go through a more intense home heating procedure to achieve pasteurization. Additionally, this pasteurizing process likewise protects the bottles from possible contamination with germs as well as bacteria.

The initial step of the Tunnel pasteurization procedure is to bring the bottles to space temperature, and afterwards start the process by filling a sterile barrier container with tap water. The clean and sterile barrier tank must go to space temperature level to ensure that the pasteurized item will certainly keep its preference and appearance. As soon as the sterilized barrier storage tank has been full of water, it is essential to remove any type of air pockets within the bottle that would prevent the pasteurized fluid from reaching its complete temperature level. This procedure is known as priming. After priming, the bottles are positioned in the warmth chamber to start the flash sterilizing process.

During the flash pasteurization procedure, the bottles' lids are placed on top of a warmth source, such as a heating element on a hot water bottle. A dial with a variable control is after that inserted right into the bottle's control box. This dial enables the temperature of the water had within the bottles to vary. The microbes existing in the faucet water will normally heat up as a result of being exposed to warm water, enabling the desired microbial count and also texture of the item to be reached.